Toilet paper packing machine will always be an increasingly great demand position without doubts because of the continuous requirement for toilet roll. The comparatively low price and the abundant need quantity is the key point to bring the company and factory the ceaseless orders. Of course, the company can get more benefits through the cheaper machine on the basis of guaranteed quality. Soontrue can satisfy these requirements totally and promise to give customers the best toilet paper making and packaging machines.

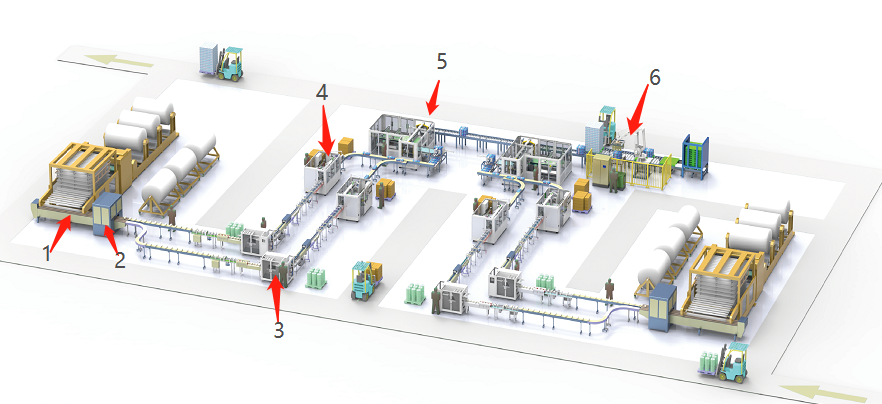

From that picture, we can see in order to manufacture toilet paper, there are generally 6 core-making steps to conduct (some steps could be replaced by manpower). And you can get every kind of the above machine from Soontrue; at the same time, Soontrue will also provide the most suitable and most cost-effective implementation plan for our customer's company according to the actual situation. Client satisfaction is our unremitting pursuit.

The above picture has perfectly shown the whole toilet roll paper production line. Number one is a rewinding machine to rewind base paper rolls in sequence into the finished paper. When the finished paper is transferred to Number 2 which is a log saw cutter, it will be cut out in the right shape and size. Then the roll of paper comes to Number 3, single roll paper packing machine. During this process, the toilet roll paper will be packed up one by one by the toilet paper packaging machine. And next, the several packed roll papers will be put into one bundle in number 4 named bag bundle packing machine, the toilet rolls are placed into the case or big bag through the number 5 which is the case packing machine. At last, the robots can pile them up neatly to save the labor power by number 6 called robot stacking system.