1. Calibrate the scale body after replacing the meter or sensor. Generally speaking, there is no need to calibrate under the common circumstances.

2. Avoid overloading, so as not to damage the sensor.

3. Periodically clean up and inspect each part of the weighing body.

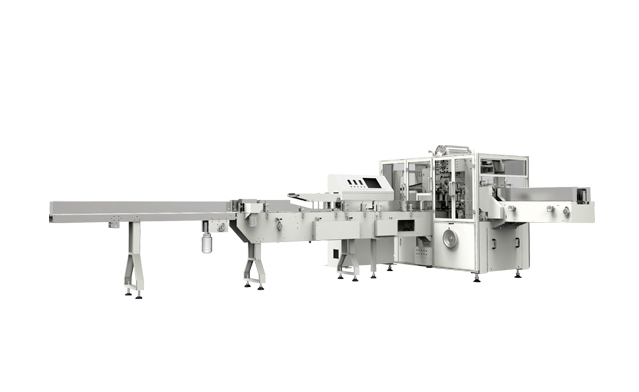

4. With regards to napkin packing machine, the oil of the motor reducer should be changed after 2000 hours of work and every 6000 hours thereafter.

5. When using the welding machine for maintenance of the scale body or its surrounding equipment, be careful not to form a current loop between the sensor and the welding handle.

6. The napkin packing machine equipment and control box have good electrical grounding.

7. The platform or steel structure supporting the scale body is stable. Do not integrate weighing body with vibration equipment.

8. The incoming materials are uniform, stable and sufficient.

9. After working every day, drain the water in the oil-water separator and refuel regularly.

10. If there is any problem with the napkin packaging machine, it should be dealt with in time to avoid the expansion of the fault and affect the production.